This is the technique that has become very popular with logo golf ball suppliers over the last 8 years. You don’t need plates, no set up time, no PMS color to be mixed. Just print and ship. UV-inks are instantly cured by UV light. Which makes it the fastes way to personalise golf balls. It’s so easy, that 104 golf balls will be ready in 30 minutes: put the balls in a tray, align them, print and ship. UV printers print a primer, ink and a gloss coating to give the print a longer lifetime and a glossy look. Not all suppliers use gloss coating. That depends on the UV printer and the time a supplier wants to spend on printing your golf balls. Matt coated means no gloss, means less protection and a shorter lifetime of the print.

Lifetime of the print

Like with pad printing inks, there can be a big difference in the lifetime of the print. UV inks need to react on the clear coating of the golf ball. If the primer doesn’t react properly, the ink breaks easily. The clear coating of Redline golf balls have been optimized for our UV inks. Which means we can guarantee a long lifetime: 72 holes.

Advantages inkjet-UV

- very affordable

- low minimum order quantity (3 to 12)

- sharp print (gets close to the print quality of pad printing)

- gloss coating gives the print a longer lifetime and a better glossy look

- longer lifetime of the print on Redline golf balls: 72 holes

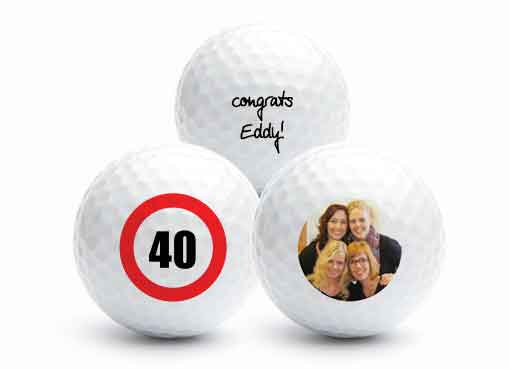

- photos and complex logos easy to print

- full color possible

Disadvantages inkjet-UV

- print area 26 mm, depends on the logo (standard 24 mm)

- PMS colors not possible